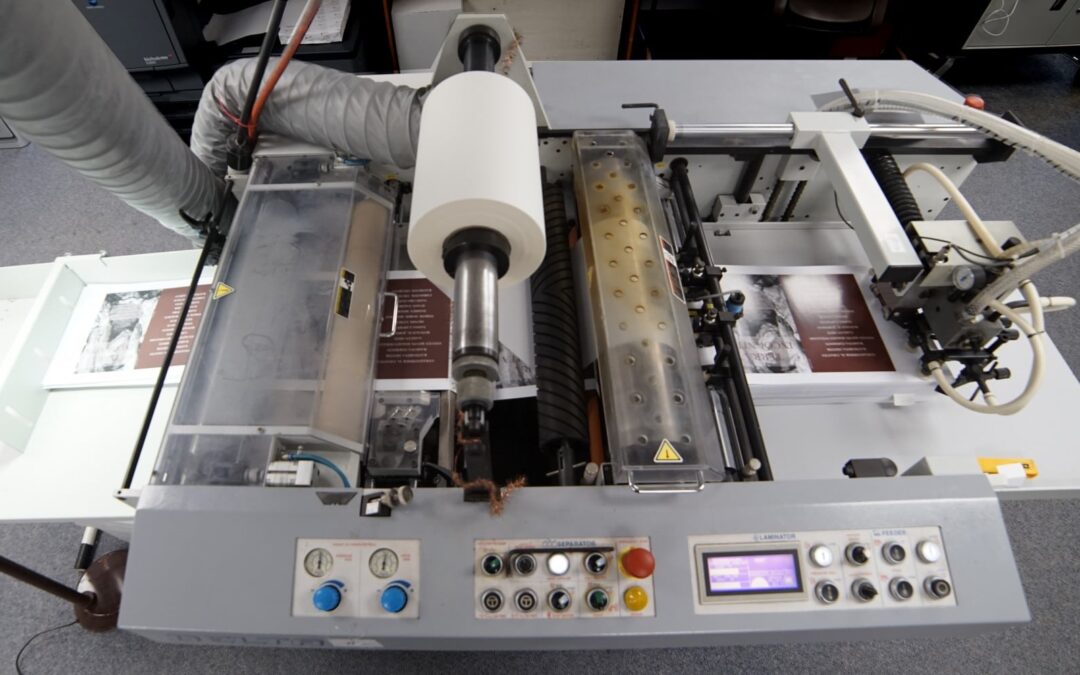

A production laminating machine, bird’s eye view. The covers move from right to left, as follows: 1) An arm with air suction cups picks up the top cover and moves it to the left between two heated lamination cylinders. (The top roller is covered by a clear plastic heat shield.) 2) Whitish lamination film feeds off the top feed roller over the top heated cylinder and down, where it is sandwiched with the printed cover under pressure and heat. Each cover is connected by the continous web of lamination film at this point. 3) After coming out of the lamination cylinders the machine angles the cover to the axis of the rollers and gives it a snap, which neatly slits the film between individual covers.