As of April 2022, our unprecedented times have become precedented. The book publishing and printing industry is still working with labor shortages, paper shortages, increased labor and material costs, and longer schedules. At Bookmobile, we’re keeping our clients up to date with our newsletter: Sign up here! But also, publishing is a great community, so I thought I’d ask some of our local publishers, partners, and friends how they’re managing: Katie Dublinski from Graywolf Press (oversees book production), John Mesjak (sales rep) from Abraham Associates, Rachel Holscher (design and offset print management) and Dieter Slezak (printshop operations) from Bookmobile, and Mark Jung (distribution) from Itasca Books.

Katie Dublinski, Associate Publisher, Graywolf Press

Graywolf Press is a nonprofit literary publisher of poetry, fiction, nonfiction, and work in translation. Among other roles, Katie oversees book production and art direction.

How is Graywolf Press adjusting to longer print schedules?

We are relying on Bookmobile to help us navigate scheduling issues – and we are spending much more time discussing where to print jobs and trying to spread them out among printers. We are working to get books to printers ahead of planned schedules, and continuing to build in extra time as we’re putting together new schedules. We’re also setting print runs much earlier than we had in the past, which involves even more guess work than before.

How does this impact your marketing plans and seasons?

We have moved publication dates for a few books; one at the last minute and others with more notice. We haven’t had to move anything out of a season yet. For one book that was substantially delayed, our publicity team relied heavily on the final PDF in lieu of print review copies (though there’s been a major shift to electronic review copies during the pandemic anyway, unrelated to print delays).

John Mesjak, Principal, Abraham Associates

Abraham Associates represents a select group of publishers and distributors and their account base includes indie and chain bookstores, museums, libraries, wholesalers, and more.

How are your publishers managing longer schedules and supply chain issues?

We’ve seen a variety of responses to supply chain issues from our different publishers. Some could be termed reactive responses and some could be considered more proactive steps.– We’ve seen pub dates slip, of course, from just a week or two to multiples months to an entire season late. There’s no point in complaining about late books – they are a fact of life right now.– Some publishers have worked with us to encourage earlier advance ordering from our indie stores by a specific deadline, to enable them to better envision what the print run should be and get it on press soon enough. In situations like that, with a firm order deadline, we used a special offer’s expiration date as a target to get those orders in.– The most important tool that we have focused on has been improved communications between our rep group and our publishers. It’s so important that we know about slipping pub dates, or deadlines, or stock issues on specific books. The more we know, the better you partner with us as reps, the better we are able to communicate those changes and situations to our customer bookstores.

Increasing book costs are a fact of life right now – some of those increasing costs in materials have to be shared down the line. They can’t all be absorbed by publishers internally! But when we’re asked, we’re arguing for a cautious, sustained look at price increases. Better to adjust a book’s price subtly as a reprint happens with a small, reasonable bump in price, instead of holding off too long and then bumping noticeably in one jump. It’s jarring to booksellers and customers in those stores when a book that was $24 comes in at $28 after the next reprint!

We’ve also seen sidelines publishers increasing their prices on various series of products all at once – giving us a heads-up that a specific line of products will be increasing as of X date. It’s probably easier to accomplish that with non-priced items like journals or gift items, when compared with books that have prices printed on them. But the uniformity of seeing everything go up a little bit makes it easier to talk about with our customers, as opposed to a piecemeal increase on this item but not that item.

How are bookstores adjusting to longer schedules to receive books? Anything publishers can do to help?

As I mentioned before, communicating with your reps and sales team about production and delivery delays is critical. The more we know in advance, the better prepared we can be when answering questions and complaints from bookstores about books that aren’t where they’re supposed to be!In general, though, aside from the highest-profile book releases, and aside from a few notable stories of containers full of cookbooks going over the side into the ocean, bookstores are well aware that printing and shipping books are taking longer than ever, and are more susceptible to unforeseen delays and are unbothered by them. There are so many books to sell!

Rachel Holscher, Director of Design & Digital Publisher Services, Bookmobile

Manages production and print buying for Coffee House Press and Graywolf Press, among others.

How are your publishers managing longer schedules?

Prescheduling with offset printers when possible, adjusting editorial/production schedules to allow more time for printing when that can work, and pushing out pub dates as a last resort. We are starting to talk about who will print projects months in advance of when we used to consider this question.

Any advice you’d like to offer?

It is necessary to be flexible with choosing quantities ahead of knowing presales, locking down page counts early, and warehouse delivery date fluctuations. And, it is good to know that everyone is experiencing these same challenges! Conversing with your print buyer / customer service team with patience as they try to help to figure out a workable solution is the way to go. There isn’t always a magic answer, but everyone is doing the best they can.

Dieter Slezak, Director of Operations, Bookmobile

Manages Bookmobile’s print production, including buying paper, overseeing schedules, etc.

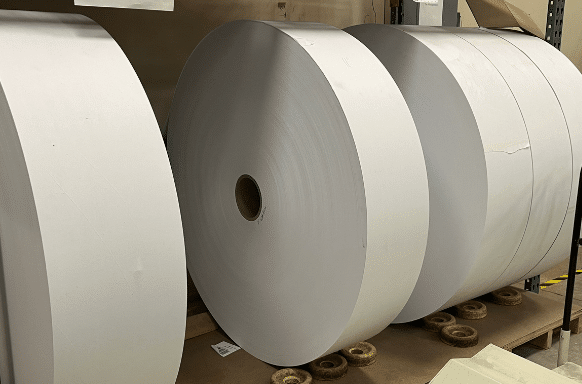

What’s happening with rising paper costs and less paper availability?

Several paper mills closed in 2019 in the US, mainly because of aging equipment and lack of profitability because of a decade of stagnant paper prices. This together with the COVID related supply chain problems led to paper shortages and hence to multiple price increases in 2022.

When do you think this will end?

Not quickly. It takes a long time to start up a paper mill and the covid supply chain issues have not been resolved yet. As a result paper availability will not improve much in 2022. Possibly in 2023 an improvement can be seen if the supply chain issues are managed better and COVID is less disruptive. Further increase in paper pricing can be expected in 2022 and 2023.

Mark Jung, Director, Itasca Books

Itasca Books is a sister company of Bookmobile, right next door, offering print distribution to the trade.

How are your publishers managing longer schedules and supply chain issues?

Primarily by managing unreasonable expectations of their authors (and their distributor). The majority of reprints and new titles are seeing delays from printers because of supply chain issues.

How are your publishers managing rising costs with materials?

Reprints are more often coming back with price increases.